Efficient material handling is at the core of successful dredging and mining operations, especially when dealing with high-solids content, abrasive slurries, and remote or submerged environments. In this context, the submersible slurry pump has emerged as a high-performance solution that simplifies installation, reduces downtime, and delivers consistent output in challenging conditions. From dredging coastal channels to dewatering tailings in deep mining pits, submersible slurry pumps—especially electric models—offer unmatched adaptability, environmental compliance, and ease of integration with modern support systems.

Built for the Abyss: Design Advantages of Submersible Slurry Pumps

Submersible slurry pumps are engineered to operate directly within the abrasive, high-solids environments they are meant to handle—whether that’s the bottom of a tailings pond, a dredging trench, or a flooded mining shaft. This fully submerged operation is one of their most critical design advantages. Unlike surface-mounted or dry-installed pumps, a submersible slurry pump does not require priming, suction lift, or external vacuum assistance to initiate flow. This eliminates common failure points and simplifies the overall pump system architecture.

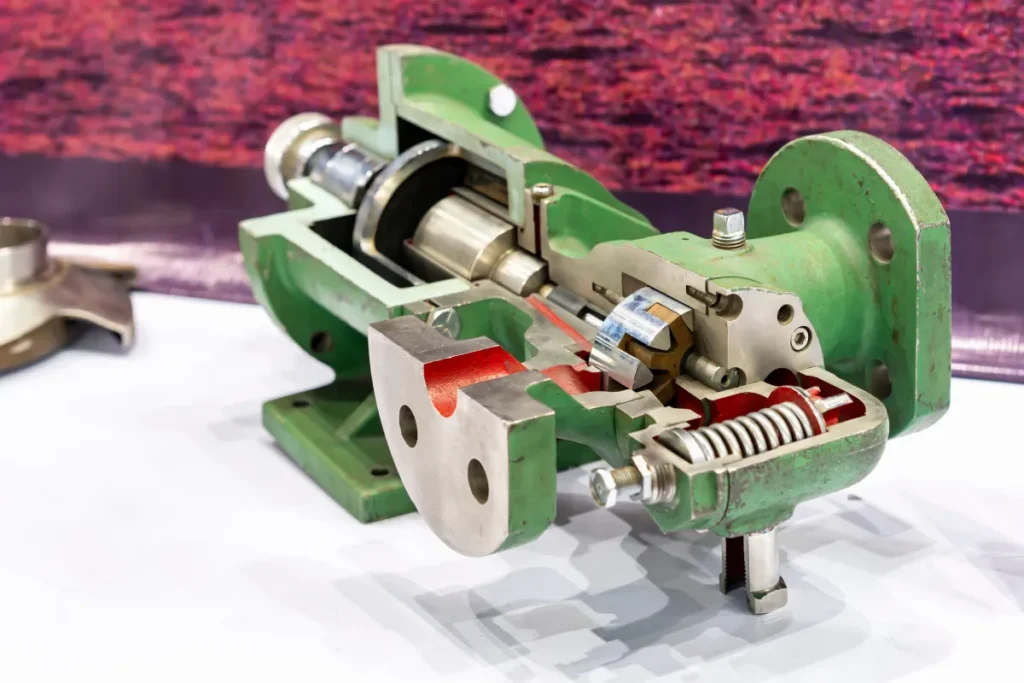

Another major benefit is the compact mechanical footprint. Traditional slurry pump systems often rely on long drive shafts, complex bearing assemblies, and external lubrication systems, all of which require extensive installation and maintenance. In contrast, submersible slurry pumps integrate the motor and pump into a single sealed unit that can be directly lowered into the slurry. This self-contained configuration removes the need for separate motor housings, alignment procedures, and coupling guards, making the setup safer and more efficient—especially in confined or hazardous environments.

When it comes to deep-set operations, electric submersible slurry pump designs offer unmatched flexibility. These pumps can be deployed vertically into deep pits, trenches, or underwater mining zones without cluttering the surface with large skid-mounted equipment. Cable-powered and often VFD-compatible, they enable variable-speed operation and automated remote control, which is ideal for dredging or dewatering tasks that require real-time responsiveness.

Durability is another key design strength. Submersible slurry pumps are typically constructed using abrasion-resistant materials to withstand prolonged exposure to sand, gravel, silt, coal fines, and other aggressive particulates. High-chrome iron alloys are often used for impellers and pump casings, offering superior wear resistance compared to standard metals. In more elastomer-focused designs, rubber-lined components offer flexibility and abrasion protection, particularly in applications involving sharp-edged debris or intermittent solids.

Head-to-Head: Submersible vs. Self-Priming and Dry-Mounted Pumps

| Feature | Submersible Slurry Pump | Self-Priming Pump | Dry-Mounted Slurry Pump |

| Suction Limitation | None (fully submerged) | Limited (~25 ft) | High dependency on suction |

| Footprint & Installation | Compact, minimal | Large, complex | Requires housing/skid |

| Energy Efficiency | High (less friction loss) | Moderate | Low |

| Noise/Vibration | Low (submerged) | Moderate-High | High |

| Maintenance Frequency | Low | Moderate | High |

From Tailings to Trenches: Where Submersible Slurry Pumps Thrive

One of the defining strengths of the submersible slurry pump lies in its unmatched versatility across a wide range of demanding applications. Whether it’s the saturated depths of a mining pit or the narrow confines of an underwater trench, these pumps are purpose-built to operate where conventional pumping systems simply cannot reach. By eliminating the need for dry installation and suction lift, submersible slurry pumps enable direct, high-efficiency fluid transfer from the source—no matter how inaccessible or abrasive the environment.

In dredging applications, submersible slurry pumps are indispensable tools for operations such as marina silt removal, pond dewatering, and underwater trenching. These pumps can be deployed directly into the sediment layer, delivering high-concentration slurry with minimal turbidity disturbance and reduced environmental impact. Their ability to operate below the waterline eliminates the risks of cavitation and flow interruptions that commonly affect self-priming or centrifugal pumps when suction conditions are inconsistent or fluctuating.

In the mining sector, submersible slurry pumps excel in applications such as tailings management, coal slurry handling, and sand and gravel extraction. These environments typically involve high-solids concentrations, sharp particulates, and corrosive fluids—conditions that quickly degrade ordinary pumping systems. A properly selected electric submersible slurry pump offers not only abrasion resistance and reliable performance but also the flexibility to be relocated as mine operations evolve or pits deepen over time. Their mobility and plug-and-play design make them ideal for rapid deployment in both surface and underground mines.

In tunneling and civil infrastructure projects, slurry removal is critical to maintaining worksite integrity and preventing flooding. Excavation runoff, bentonite slurry, and spoil water must be removed quickly and continuously. Submersible slurry pumps—especially those equipped with agitators or jetting rings—can efficiently handle thick slurry mixes without clogging, ensuring uninterrupted progress in confined spaces where large pump skids or intake hoses are not feasible.

Continuous Operation Without Downtime: Key Operational Advantages

A defining trait of the submersible slurry pump is its ability to deliver consistent, uninterrupted performance in some of the most abrasive and challenging environments. By design, these pumps eliminate many of the operational delays and failure points associated with traditional slurry pumping systems—making them ideal for continuous-duty applications in dredging, mining, and infrastructure projects.

Since the pump is already submerged in the slurry, there’s no need for priming—a step that often introduces delays, air lock issues, or cavitation risks in self-priming or dry-mounted systems. This allows for immediate startup and rapid response, which is especially valuable in applications like emergency pond dewatering, slurry bypassing, or time-sensitive dredging windows. Whether it’s an automated control system or a manual switch, operators can count on the submersible slurry pump to begin moving material without hesitation.

Another operational advantage is the pump’s sealed, self-contained construction. With fewer moving parts exposed to the external environment, there is a reduced risk of clogging, corrosion, or impact damage from floating debris. Maintenance cycles are naturally extended, and unexpected shutdowns are minimized. Moreover, the motor and impeller alignment is factory-set and sealed, eliminating common issues caused by shaft misalignment or coupling wear—problems that often lead to vibration, inefficiency, and mechanical failure in traditional pump assemblies.

In the case of an electric submersible slurry pump, integration with variable frequency drives (VFDs) offers even greater operational control. VFDs enable operators to dynamically adjust pump speed to match fluctuating flow rates or solids content, eliminating the need for throttling valves or bypass piping. This not only conserves energy but also reduces wear and tear on the system, extending equipment life and lowering the total cost of ownership.

Maintenance Matters: Why These Pumps Simplify Your Workflow

In operations where downtime translates to lost revenue and increased safety risks, the submersible slurry pump stands out for its simplicity and serviceability. Unlike traditional slurry pumps, which require elaborate mounting setups, alignment checks, and lubrication systems, submersible slurry pumps are designed with plug-and-play modularity, making them easy to install, retrieve, and replace with minimal disruption to ongoing operations.

The modular design extends beyond installation. Whether you’re dealing with dredging pits, tailings ponds, or slurry-filled shafts, maintenance crews can quickly lift the pump using integrated lifting points, perform routine checks, and redeploy the unit without needing specialized alignment tools or extensive disassembly. This greatly reduces the man-hours and equipment typically required for servicing dry-mounted or skid-based slurry pumps.

From a mechanical standpoint, submersible slurry pumps feature fewer external seals, eliminating the need for external lubrication systems. This not only minimizes failure points but also eliminates common leak risks that can damage surrounding infrastructure or contaminate sensitive sites. Internal seal systems are protected from abrasive slurry exposure, and high-quality mechanical seals—often in tandem configurations—ensure long service life in demanding applications.

The enclosed motor housing provides an additional layer of protection, shielding critical components from external corrosion, moisture ingress, and dust contamination. Especially in coastal dredging or acidic mining environments, this sealed design helps preserve motor integrity and electrical reliability over time, reducing the likelihood of sudden failures or electrical hazards.

These design efficiencies translate into significant long-term savings. Lower labor requirements, reduced parts inventory, and extended service intervals contribute to reduced operational expenditures (OpEx), while the simplified design and faster deployment cycles help optimize capital expenditures (CapEx). Over multi-year use cycles, organizations that rely on electric submersible slurry pumps benefit from a more predictable maintenance schedule, reduced total cost of ownership, and improved return on investment in equipment.

Electric Submersible Slurry Pump: A Cleaner, Greener Solution

As industries move toward more sustainable operations, the electric submersible slurry pump is emerging as a vital solution for environmentally conscious dredging and mining projects. Unlike diesel-driven systems, which contribute to onsite emissions, noise pollution, and regulatory headaches, electric submersible slurry pumps offer a zero-emission alternative that supports cleaner operations—especially in ecologically sensitive or heavily regulated areas.

In coastal dredging, municipal waterway maintenance, or protected wetland restoration, diesel fumes and oil leaks can pose significant environmental risks. Electric submersible slurry pumps eliminate these concerns, making them ideal for applications where regulatory compliance and environmental stewardship are top priorities. Their sealed, submersible design also reduces the risk of hydraulic spills or fuel contamination.

Another key advantage is their compatibility with renewable energy sources. These pumps can be powered through solar arrays, battery banks, or hybrid energy systems, particularly in remote areas where grid access is limited or diesel logistics are costly. With the growing emphasis on reducing carbon footprints, integrating submersible slurry pumps into clean energy frameworks helps contractors meet both performance and sustainability benchmarks.

Beyond power source flexibility, electric submersible slurry pumps are highly automation-ready. They can be integrated into modern control systems such as RTK GPS for dredge positioning, SCADA systems for remote monitoring, and IoT platforms for predictive maintenance alerts. This makes them a preferred option in smart mining operations and digitally managed dredging fleets, where centralized control and data-driven optimization are key.

Their low-noise operation and absence of exhaust emissions also make electric submersible slurry pumps suitable for urban infrastructure projects, offshore mining, and inland waterways where environmental and community impact must be tightly controlled. As ESG mandates tighten across sectors, the adoption of electric submersible systems is no longer just an operational choice—it’s a strategic move toward cleaner, safer, and more future-ready material handling.

Beyond the Pump: Supporting Systems That Maximize Submersible Efficiency

While the submersible slurry pump is the core of many high-solids transport operations, its performance can be significantly amplified with the right supporting systems. When configured with smart accessories and structural components, submersible slurry pumps evolve from standalone tools into integrated dredging or dewatering solutions capable of handling complex site conditions, variable material loads, and demanding production targets.

One of the most effective ways to enhance the productivity of submersible slurry pumps is through the integration of jetting rings, agitators, and cutter heads. Jetting rings help fluidize compacted or consolidated material, loosening dense layers of sand, silt, or sludge before they reach the pump intake. Agitators positioned near the pump inlet continuously stir settled solids, preventing clogging and maximizing slurry concentration. For more abrasive or cohesive materials, such as clay or packed sediment, hydraulically driven cutter heads provide the necessary mechanical breakup, ensuring consistent flow and reducing suction losses.

Advanced installations often incorporate remote monitoring systems and telemetry integration, particularly in applications where pumps are deployed in deep pits, offshore environments, or unmanned locations. Sensors can track flow rate, pressure, vibration, and motor temperature in real time, feeding data into SCADA platforms or mobile dashboards. This not only improves operational visibility but also enables predictive maintenance, reduces unplanned downtime, and optimizes pump efficiency under dynamic site conditions.

For mobile dredging setups, the use of flotation pontoons, lift frames, and cable hoisting systems allows submersible pumps to be repositioned with ease. Pontoons provide buoyant support in shallow water bodies, enabling lateral movement across dredge zones. In deeper or landlocked pits, hoisting systems mounted on gantries or excavators help lower and maneuver the pump with precision. These structural accessories are crucial for reaching difficult zones, adjusting working depth, and ensuring pump intake remains in optimal material flow paths.

Each of these elements—whether mechanical, digital, or structural—serves to extend the functional reach of submersible slurry pumps, enabling them to handle more abrasive, variable, or remote materials with greater reliability. As slurry management becomes increasingly site-specific, understanding and leveraging these supporting systems becomes essential to unlocking the full potential of your submersible pump setup.

What to Look for in a Submersible Slurry Pump Provider

Selecting the right submersible slurry pump is only part of the equation—choosing a provider with the technical depth, product integrity, and after-sales support to back it up is equally critical. Whether you’re deploying pumps in dredging, mining, tunneling, or industrial wastewater applications, the complexity of these environments demands more than off-the-shelf equipment. It requires a partner who can tailor solutions, anticipate operational challenges, and ensure long-term reliability and stability.

A key differentiator is the material selection, especially for high-wear components such as the impeller, volute, and wear plates. Look for providers who offer impellers cast in high-chrome white iron (typically ≥ 25% chromium) for maximum abrasion resistance, along with elastomer-lined options for applications involving sharp debris or fluctuating particle loads. The motor insulation class—such as Class H for high-heat endurance—and mechanical seal configuration (single, tandem, or cartridge-style) should also align with the thermal, chemical, and abrasive demands of your specific site.

Equally important is the provider’s application engineering capability. A competent vendor should evaluate your site’s slurry characteristics (solids concentration, particle size distribution, pH, viscosity), required head and flow rate, power source availability, and duty cycle to recommend the optimal submersible slurry pump configuration. This includes guidance on impeller size, motor power, flow velocity, and NPSHr (net positive suction head required)—all of which directly affect pump efficiency and lifespan.

Safety cannot be overlooked, especially for electric submersible slurry pumps deployed in wet or submerged environments. Look for integrated thermal overload protection, moisture ingress sensors, and cable sealing systems that prevent short-circuits, overheating, or water damage. Some providers even offer explosion-proof or ATEX-certified models for hazardous zones, as well as VFD-compatible designs for adjustable speed control and protection during startup.

Finally, consider the service ecosystem around the pump. Top-tier providers offer not just product sales but also rental options for short-term or trial deployments, preventive maintenance contracts, and remote diagnostic support. Access to spare parts, repair kits, and responsive field technicians ensures that even in the event of failure, downtime remains minimal.

In high-stakes operations where slurry pumps often run 24/7 under punishing conditions, working with the right provider can mean the difference between consistent output and costly delays. Evaluating a supplier’s technical expertise, customization capabilities, safety features, and post-sale support is essential to building a resilient pumping system that can meet both current and future demands.

Submersible Slurry Pumps as a Strategic Investment

As the demand for high-efficiency, low-maintenance slurry management grows across various industries, the advantages of deploying a submersible slurry pump are becoming increasingly difficult to ignore. Their ability to operate directly at the slurry source, combined with modular accessories and intelligent controls, makes them ideal for both rugged field conditions and environmentally sensitive projects. If you’re exploring advanced slurry pumping solutions for dredging, mining, or civil infrastructure projects, we at WA Dredge Contractors can help you design and implement systems tailored to your specific operational goals. Contact us to learn how we can support your next project with cutting-edge, dependable pump technology.