Slurry pumps are vital components in industries that involve the handling and transport of abrasive, viscous, or solid-laden materials, such as mining, dredging, and wastewater treatment. Choosing the right slurry pumps supplier is essential for ensuring operational efficiency, minimizing downtime, and optimizing the lifespan of equipment. With the wide variety of slurry pump types available, it’s crucial to partner with a supplier who understands your specific needs and offers high-quality products, excellent customer support, and innovative solutions. This article outlines the key qualities to look for in reliable slurry pump suppliers, helping procurement and engineering teams make informed decisions when selecting the best pump for their operations.

Industry Expertise and Technical Knowledge

In-depth knowledge of slurry systems is crucial for selecting reliable slurry pumps that can operate optimally in demanding environments. Slurry pumps are designed to move mixtures of liquids and solid particles, but depending on the application, these slurries can vary in consistency, abrasiveness, and chemical composition. This makes it crucial for suppliers to have a strong understanding of the specific demands of the slurry being pumped. Without the proper expertise, issues such as pump wear, clogging, and inefficient performance can arise, leading to costly repairs and downtime. The correct slurry pump design and materials can help minimize these problems and ensure the pump operates efficiently for a longer period.

Selecting slurry pump suppliers with industry-specific expertise yields substantial benefits. Suppliers who specialize in sectors such as mining, dredging, and processing understand the unique challenges and environmental conditions that each industry faces. In mining, for example, the slurries can be highly abrasive, requiring pumps made from durable materials to withstand wear and tear. In dredging, pumps must be able to handle materials ranging from sand to silt, often in submerged conditions. For industrial processing, pumps may need to manage highly viscous or corrosive fluids. Suppliers familiar with these nuances can offer more targeted advice and recommend the right solutions for your specific needs, thereby improving operational efficiency and reducing the risk of operational delays.

Furthermore, slurry pump manufacturers who are committed to innovation and adapting to application-specific challenges are invaluable partners. These manufacturers actively seek out new materials, technologies, and design features that improve pump performance and longevity. For instance, the development of advanced, wear-resistant materials for pump components helps extend the pump’s life, especially in abrasive environments. Additionally, manufacturers who innovate in pump efficiency, such as those integrating automated monitoring or optimizing energy consumption, help operators reduce operational costs and improve overall system performance. A supplier who works closely with manufacturers on the cutting edge of pump technology is better positioned to provide pumps that deliver enhanced performance under unique conditions.

By partnering with experienced slurry pump suppliers who understand the specific demands of your industry, you can be confident that you are investing in pumps that will meet your operational needs. These suppliers can offer high-quality slurry pump parts, as well as tailored advice and support, to help ensure that your equipment continues to perform at its best, even in the most demanding environments.

Range and Availability of Products

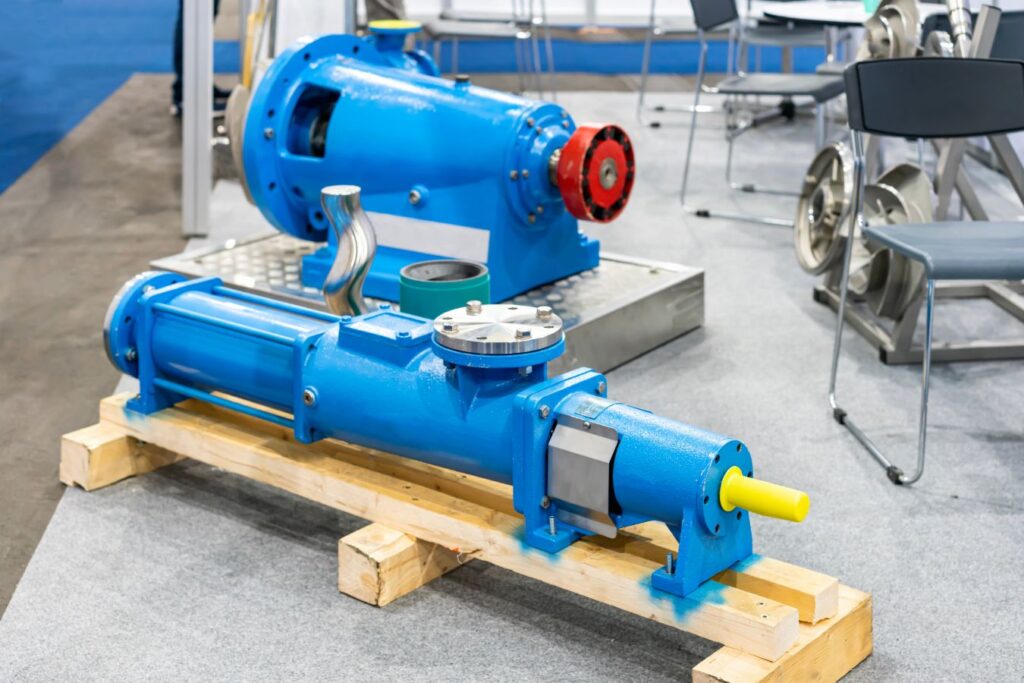

Having access to a wide selection of slurry pump types is crucial when selecting the right equipment for specific industrial applications. Not all slurry systems are the same, and different environments and operational requirements demand different types of pumps. Reliable slurry pump suppliers offer a range of options, including vertical, submersible, and centrifugal slurry pumps, each designed for specific tasks and conditions. Vertical pumps, for example, are often used in sump applications or to pump liquids with high levels of solids from deep pits. Submersible pumps are ideal for applications that require the pump to be fully submerged in the slurry, providing reliable service in dredging and wastewater management. Centrifugal slurry pumps, renowned for their ability to handle high flows at moderate pressures, are often selected for large-scale operations such as mining and chemical processing. Having access to a broad range of these pump types ensures that you can select the most suitable pump for your specific application, improving operational efficiency and reducing downtime.

Customizable solutions are also a crucial factor when selecting a slurry pump supplier. Every slurry pumping operation is unique, with different flow rate requirements, pump head, and solids content. A good supplier understands these variables and can offer pumps tailored to meet specific needs. For example, adjusting the impeller size or material for more effective solids handling, optimizing the pump head for specific discharge distances, or configuring the pump to handle varying flow rates can significantly impact performance. Reliable slurry pump manufacturers offer customized pumps that can be tailored to meet specific parameters, ensuring your equipment operates optimally under the unique conditions of your operations. Customization is especially crucial for industries dealing with complex slurries, such as mining, dredging, or wastewater treatment, where conditions can change frequently and equipment must adapt accordingly.

In addition to the variety of pump types and customization options, the availability of compatible slurry pump parts is essential for minimizing downtime and ensuring the longevity of the equipment. A dependable slurry pump supplier should offer a wide range of spare parts that are designed to work seamlessly with the pumps they supply. Having access to high-quality, compatible slurry pump parts ensures that any necessary repairs or maintenance can be carried out quickly and effectively, reducing the risk of prolonged operational interruptions. Whether it’s replacement seals, impellers, bearings, or other key components, a supplier that provides readily available spare parts helps maintain your equipment in optimal condition and supports the smooth operation of your business.

By partnering with slurry pump suppliers that offer a comprehensive range of pump types, customizable solutions, and an extensive inventory of slurry pump parts, you can ensure that your slurry pumping system is always tailored to the demands of your industry while minimizing downtime and maximizing operational efficiency.

Quality of Components and Manufacturing Standards

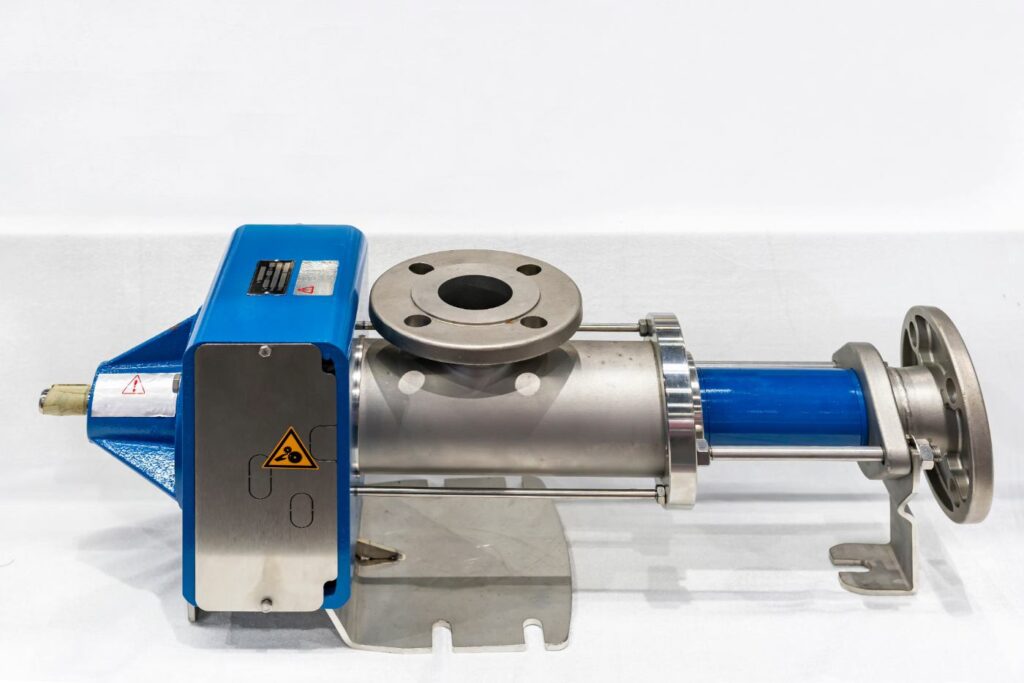

The quality of materials used in the construction of slurry pumps plays a pivotal role in their performance, longevity, and reliability. Slurry pumps operate in demanding environments, often handling abrasive, corrosive, or high-temperature materials that can rapidly degrade inferior components. To ensure the pump’s durability and efficient operation, it is crucial to select a slurry pump supplier that utilizes high-quality materials, such as high-chrome alloys, elastomers, and stainless steel. These materials offer superior resistance to abrasion, corrosion, and wear, ensuring that the pump components can withstand harsh conditions without frequent breakdowns or performance losses. High chrome materials, for instance, are commonly used in the construction of the pump’s wet end components, such as impellers and casings, to enhance abrasion resistance when handling solid-laden slurries. Stainless steel, renowned for its resistance to corrosion, is frequently utilized in components that come into contact with corrosive slurries or chemicals, making it an ideal choice for a wide range of industrial applications. Elastomers are also widely used for seals and gaskets, providing flexibility and resistance to wear, temperature fluctuations, and chemical attacks. When selecting a slurry pump supplier, it’s essential to ensure that durable materials are used to guarantee the equipment’s reliability and efficiency over time.

Another essential factor to consider when selecting slurry pump suppliers is their adherence to global industry certifications and manufacturing standards. Leading slurry pump manufacturers are often certified to international standards such as ISO (International Organization for Standardization), ANSI (American National Standards Institute), or API (American Petroleum Institute). These certifications ensure that the manufacturer’s processes, materials, and products meet rigorous quality control guidelines and are tested to perform under the highest standards. ISO standards, for example, focus on quality management systems, while ANSI and API standards emphasize safety, reliability, and performance in the oil, gas, and industrial pumping sectors. Working with suppliers who comply with these standards assures that the slurry pumps you receive will deliver reliable performance, meet safety regulations, and be compatible with other industry-specific systems.

Consistency in manufacturing practices is also critical to maintaining the high performance of slurry pumps. Reputable slurry pump manufacturers implement strict quality control procedures to ensure that each pump meets the same high standards, no matter the order size or frequency. These practices include rigorous testing at various stages of production, such as material inspection, performance testing, and final product verification. By selecting a slurry pump supplier with strong quality control measures, you can be confident that each pump and its slurry pump parts will meet your expectations for performance, durability, and efficiency. Consistency in manufacturing also ensures that spare parts and replacements are of the same high quality as the original components, providing seamless maintenance and reducing the risk of failure in critical operations.

Ultimately, the quality of materials, adherence to international certifications, and consistency in manufacturing practices are vital factors in ensuring that the slurry pumps you invest in are durable, reliable, and capable of performing in the toughest industrial environments.

After-Sales Support and Spare Parts Availability

After-sales support and spare parts availability are vital components of a successful partnership with slurry pump suppliers. Even the most reliable slurry pumps will require maintenance, troubleshooting, or occasional repair to ensure they continue operating at peak efficiency. This is where strong technical support, training, and maintenance assistance become indispensable. A slurry pumps supplier that offers comprehensive technical support can help diagnose issues, provide solutions, and ensure the pump is optimized for your specific needs. Whether it’s a simple pump adjustment or a more complex technical issue, having access to expert advice and troubleshooting can significantly reduce downtime and operational interruptions. Additionally, the supplier’s training services can ensure that your team is fully equipped to operate and maintain the slurry pumps, which in turn helps improve overall system performance and safety.

The availability of slurry pump parts with quick lead times is another essential factor in minimizing downtime and ensuring that operations continue smoothly. In industries such as mining, dredging, and wastewater treatment, even brief periods of downtime can result in substantial financial losses and delays. Therefore, suppliers that can quickly deliver the necessary slurry pump parts—such as seals, impellers, bearings, and motors—are invaluable. This ensures that any issues can be swiftly addressed without disrupting ongoing projects. A supplier with an efficient supply chain and a large inventory of spare parts can quickly dispatch the required components, thereby reducing maintenance delays and avoiding extended downtime.

Furthermore, the value of suppliers with a global or regional support network cannot be overstated. A slurry pumps supplier with a broad geographical reach ensures that you can receive assistance regardless of where your operations are located. Whether you are operating in remote mining locations or busy industrial sites, having local or regional access to technical support, maintenance services, and spare parts is crucial. A strong network of support enables suppliers to provide timely, on-site service when needed, ensuring your equipment remains operational. This support infrastructure also plays a crucial role in reducing overall maintenance costs by providing quicker access to the right resources, streamlining repair processes, and minimizing operational delays.

Customization and Engineering Capabilities

One of the key benefits of partnering with experienced slurry pumps suppliers is the ability to customize slurry pumps to meet the specific demands of harsh or unique operational environments. Whether you are working in mining, dredging, or industrial processing, the conditions you face—such as abrasive slurries, high temperatures, or corrosive environments—require pumps that are specially engineered for durability and efficiency. A reliable slurry pumps supplier understands these challenges and offers tailored solutions that can be adjusted in terms of materials, size, and design to suit your operational needs. For example, pumps used in mining may require reinforced components to handle highly abrasive solids, while pumps used in dredging may need to be built to operate submerged under extreme pressure. Customization ensures that the pump performs optimally, minimizing wear and tear and extending its operational lifespan.

In addition to offering customized pumps, reputable slurry pump manufacturers often provide engineering consultation and on-site assessment services. These services are invaluable for ensuring that the right pump is selected based on the unique characteristics of the slurry being pumped, as well as the specific requirements of the operational environment. A thorough on-site assessment can help identify potential issues, such as challenging pumping conditions, varying flow rates, or temperature fluctuations, and allow engineers to design a pump that is specifically tailored to address these factors. By working closely with a supplier’s engineering team, companies can ensure that their slurry pumps are optimally configured to handle their specific application, thereby reducing operational inefficiencies and extending the equipment’s lifespan.

Furthermore, many industries today are adopting automation and telemetry systems to enhance efficiency, improve monitoring, and reduce maintenance costs. Leading slurry pump suppliers and manufacturers offer integration with these advanced systems, enabling real-time data collection, remote monitoring, and predictive maintenance. By incorporating smart sensors, flow meters, and other monitoring tools into the pump system, operators can gain valuable insights into performance metrics such as pressure, flow rate, and pump condition. This integration enables the detection of issues before they lead to pump failure, ensuring proactive maintenance and reducing costly downtime. The ability to integrate slurry pumps with automation systems provides operators with greater control over their operations and helps optimize the performance of the pump, especially in complex or high-volume applications.

Transparent Pricing and Procurement Flexibility

Transparent pricing is a crucial factor when selecting a slurry pump supplier, as it enables businesses to make informed purchasing decisions and avoid unexpected costs in the future. A reliable supplier will offer clear, detailed pricing that includes all aspects of the product and service, from initial pump costs to any additional fees for installation, maintenance, or spare parts. By choosing suppliers who prioritize transparency, you ensure that the financial aspects of your procurement process are straightforward, preventing any surprises that could affect your budget. Competitive pricing is also crucial in maintaining cost-effectiveness, particularly for long-term projects or large-scale operations where equipment costs can quickly accumulate. Slurry pump manufacturers who offer competitive rates without sacrificing quality help businesses maximize their return on investment, ensuring that the pumps provided are both affordable and reliable.

In addition to transparent pricing, the availability of flexible purchasing models is a significant advantage. Many industries face fluctuating cash flow or project-specific budgeting challenges, which is why it’s crucial to work with suppliers of slurry pumps who offer various procurement options. Flexible models, such as rentals, capital expenditure (CAPEX), or operating expenditure (OPEX), enable businesses to tailor their purchases to their financial situation. Rental options, for example, are ideal for short-term projects or when there is uncertainty about the long-term need for a pump, allowing businesses to avoid large upfront costs. On the other hand, CAPEX and OPEX models offer companies the flexibility to spread payments over time, which can help manage cash flow. A supplier that offers these options demonstrates an understanding of the financial challenges their customers may face and provides solutions that cater to different business needs.

Furthermore, reliable slurry pump suppliers streamline the quoting, ordering, and delivery process, simplifying procurement for their customers. Efficient quoting systems ensure that businesses can quickly obtain accurate pricing information for the pumps and spare parts they need, helping to expedite decision-making. A user-friendly online ordering system or customer portal can simplify the process of tracking orders, managing invoices, and requesting quotes. Additionally, reputable suppliers will offer prompt and reliable delivery services to ensure that the necessary slurry pumps and slurry pump parts arrive on time, minimizing delays in projects and reducing the risk of downtime. By choosing suppliers who offer simplified processes and fast, reliable delivery, businesses can ensure that their slurry pumping systems are always operational and ready for use.

Working with slurry pumps suppliers that offer transparent pricing, flexible procurement models, and streamlined ordering and delivery processes helps businesses save time and money while ensuring that they have the right equipment available when needed.

Environmental and Regulatory Compliance

Environmental and regulatory compliance are critical considerations when choosing slurry pump suppliers, especially in industries that operate in sensitive or regulated environments. As sustainability becomes an increasingly important focus across all sectors, suppliers who offer eco-conscious solutions or energy-efficient designs can help businesses meet both environmental and regulatory standards. Pumps designed with energy efficiency in mind not only reduce operational costs but also minimize the environmental impact of your operations. Energy-efficient slurry pumps are particularly beneficial in industries such as mining, wastewater treatment, and dredging, where pumps are used continuously or for extended periods. By using pumps that consume less power, businesses can reduce their carbon footprint while maintaining performance standards.

Additionally, slurry pump manufacturers that prioritize eco-friendly designs often incorporate advanced materials and technologies that reduce waste, improve efficiency, and extend the lifespan of the pumps. For example, pumps made from durable, corrosion-resistant materials, such as stainless steel or high-chrome alloys, tend to last longer, requiring fewer replacements and generating less waste. Manufacturers that focus on reducing the environmental impact of their products contribute to the broader goals of sustainable industrial practices.

Adherence to local and international environmental regulations is also crucial when selecting slurry pump suppliers. Compliance with industry standards such as ISO 14001 for environmental management systems, or specific regional regulations like those governing emissions or water discharge, ensures that the pumps provided meet the required legal and environmental standards. This is especially important in industries such as oil and gas, where stringent environmental regulations govern waste management and water use, and in mining, where the handling of potentially hazardous materials requires strict adherence to environmental guidelines. By selecting suppliers committed to meeting these regulatory requirements, businesses can ensure they avoid potential fines, legal issues, and reputational damage.

In sectors such as mining, oil and gas, and wastewater treatment, the importance of working with slurry pump suppliers who are committed to environmental and regulatory compliance cannot be overstated. These industries often face stricter regulations and higher scrutiny due to their environmental impact. Choosing suppliers who provide pumps that are not only reliable but also environmentally conscious helps ensure that operations remain compliant, reduce their environmental impact, and align with sustainability goals.

Conclusion

In conclusion, selecting a reliable slurry pump supplier is critical to the success of any operation involving slurry transport. From offering a wide range of products and customizable solutions to providing exceptional after-sales support and ensuring regulatory compliance, the right supplier can significantly impact the efficiency and sustainability of your operations. By considering factors such as technical expertise, transparent pricing, and commitment to innovation, businesses can make informed choices that enhance performance, reduce costs, and maintain operational continuity for the long term.