Submersible slurry pumps have become essential tools for industries that handle abrasive, high-solid-content fluids in demanding environments. From mining and construction to dredging and wastewater treatment, these pumps are engineered to operate underwater while moving heavy slurries with efficiency and durability. This article explores the engineering principles, types, key features, and practical applications of submersible slurry pumps, along with insights into the differences between hydraulic submersible slurry pumps and electric submersible slurry pumps, to help users select and operate the right equipment for their specific needs.

How Submersible Slurry Pumps Work

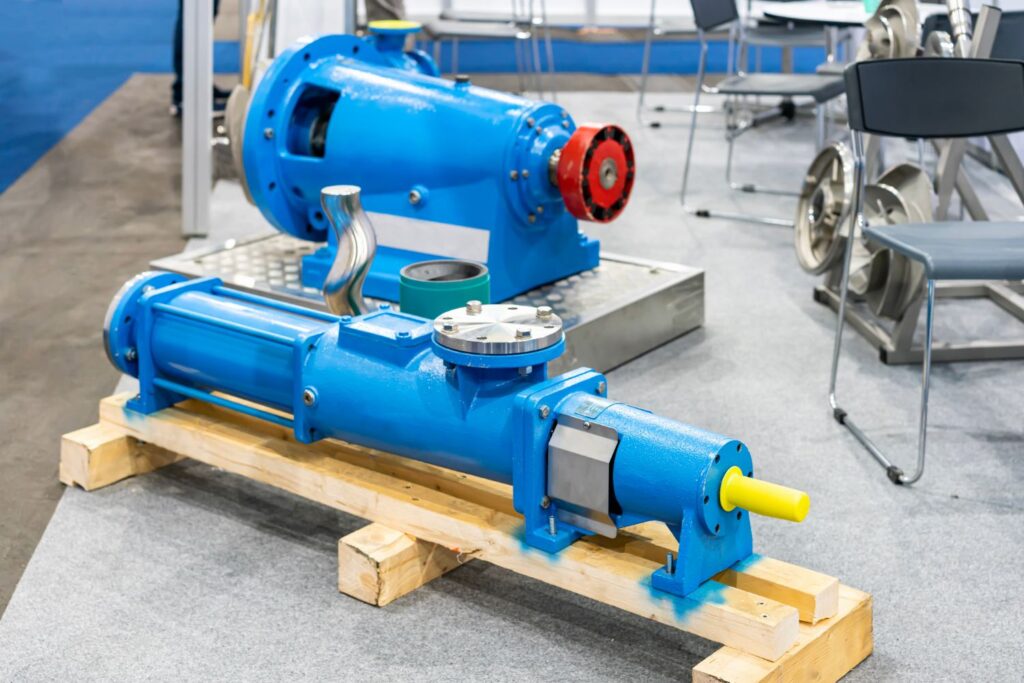

A submersible slurry pump is specifically engineered to operate while fully submerged in slurry—a mixture of liquid and solid particles. Unlike standard water pumps, these units are built to handle highly abrasive, viscous, and dense fluids, making them essential for operations involving mining tailings, dredged material, or industrial waste. Their unique capability lies in the way they directly sit in the pumped material, allowing efficient fluid movement without the need for priming or suction lines.

One of the key distinctions between a submersible slurry pump and a standard submersible water pump is its ability to handle solids without clogging or experiencing rapid wear. Water pumps are typically designed for clean or lightly contaminated fluids, whereas slurry pumps must manage abrasive particles like sand, silt, gravel, and industrial sludge. This calls for more robust internal components and specialized design features that ensure reliability under harsh conditions.

At the core of the pump is an integrated motor that is hermetically sealed to prevent fluid ingress. In an electric submersible slurry pump, this motor is powered by an electrical connection and is often equipped with thermal sensors and overload protection to prevent damage. In a hydraulic submersible slurry pump, the motor is driven by hydraulic power, allowing for high torque performance in remote or underwater environments without direct electrical access.

Impeller design plays a critical role in slurry handling. These pumps often feature semi-open or vortex-style impellers that create a strong centrifugal force to move dense mixtures efficiently while reducing the risk of clogging. Additionally, advanced sealing systems—such as double mechanical seals with protective oil chambers—are employed to prevent slurry from reaching the motor and causing failure.

With a focus on rugged durability, motor integration, and optimized impeller and sealing configurations, the submersible slurry pump is a reliable solution for demanding fluid transfer tasks across various industrial applications.

Key Engineering Features and Design Considerations

The performance and longevity of a submersible slurry pump depend heavily on its engineering and material composition. These pumps are designed to operate in aggressive environments where abrasion, corrosion, and continuous wear are common. For this reason, the materials used in construction—such as high-chrome alloys, hardened steel, and specialized elastomers—must resist damage from coarse solids and chemically reactive fluids. The right material selection directly impacts maintenance frequency, pump lifespan, and cost-effectiveness.

Impeller design is another critical factor in slurry pump engineering. Depending on the application, submersible slurry pumps may use vortex, semi-open, or fully closed impellers. Vortex impellers are ideal for handling large solids and fibrous materials, as they minimize contact between the impeller and abrasive slurry. Semi-open impellers offer a balance between solids handling and hydraulic efficiency, while closed impellers are typically reserved for low-solid, high-efficiency systems. The choice of impeller influences not only the pump’s durability but also its ability to maintain continuous flow under varying slurry conditions.

The seal system in a submersible slurry pump plays a vital role in protecting the internal motor. Double mechanical seals, often housed within an oil-filled chamber, are commonly used to prevent slurry infiltration and resist pressure fluctuations. These seals must be robust enough to withstand abrasive particles and fluid ingress, which are frequent causes of pump failure.

Motor cooling is another important design aspect, particularly in both hydraulic submersible slurry pump and electric submersible slurry pump configurations. Electric models rely on water jackets or external cooling systems to dissipate heat generated during operation. In hydraulic models, the hydraulic fluid itself aids in cooling and lubrication, offering efficient performance even in submerged or remote applications.

Lastly, critical performance metrics such as head pressure, flow rate, and solid-handling capacity must align with the specific needs of the application. A well-designed submersible slurry pump should maintain high throughput while handling large solids and minimizing wear, ensuring consistent, reliable operation in the most demanding industrial environments.

Types of Submersible Slurry Pumps

Submersible slurry pumps are available in various configurations, each designed to meet specific operational demands across industries like mining, construction, wastewater treatment, and dredging. While all models share the ability to operate fully submerged in abrasive slurry, their performance and application suitability can vary significantly based on power source and mobility.

The two most common types are the electric submersible slurry pump and the hydraulic submersible slurry pump. Both are engineered for durability and high solids handling but differ in power delivery, installation flexibility, and field performance.

Electric Submersible Slurry Pump

An electric submersible slurry pump is powered by an integrated electric motor, making it ideal for stationary or semi-permanent installations. These pumps are typically used in environments where electrical infrastructure is readily available, such as in wastewater treatment plants, industrial sumps, or settled ponds. They are known for energy efficiency and relatively low operating noise. Because they are often operated from a fixed power supply, electric models are especially well-suited for long-duration or continuous-duty operations.

Electric models often come equipped with motor protection features like thermal sensors, overload protection, and variable frequency drives (VFDs) for enhanced control. Their compact design and ease of automation make them a popular choice for facility-based pumping systems.

Hydraulic Submersible Slurry Pump

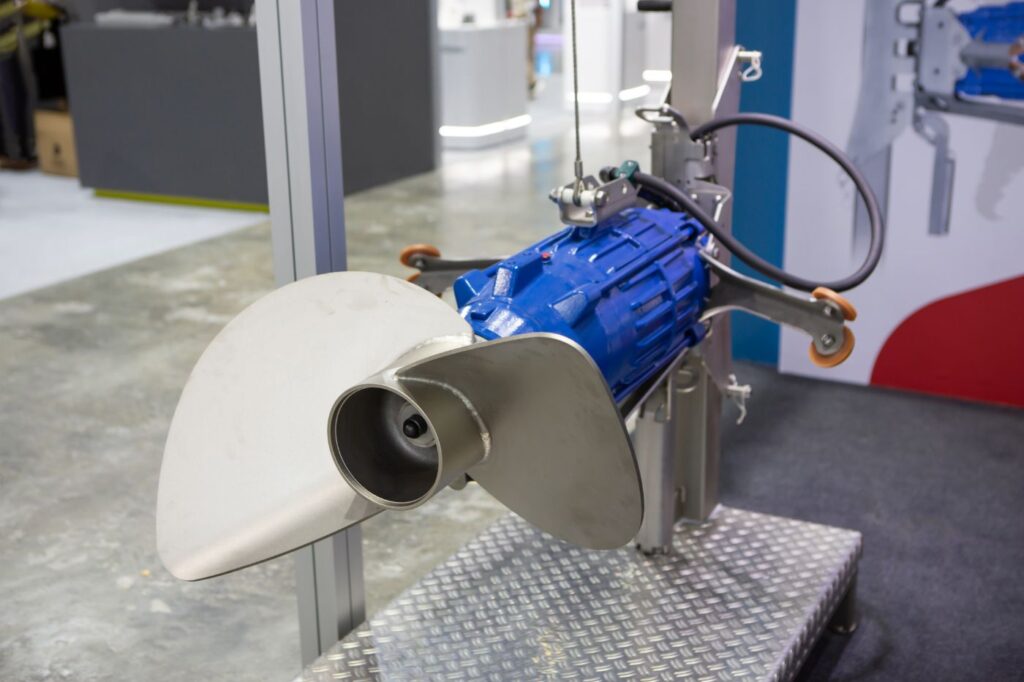

A hydraulic submersible slurry pump, on the other hand, is driven by hydraulic power units (HPUs), making it highly adaptable for mobile or remote applications. These pumps are commonly used in dredging operations, dewatering flooded excavation sites, or mining pits where electric power may not be accessible. Hydraulic models deliver high torque and performance even under extreme conditions, including high solids content and abrasive slurries.

Because they are not tethered to an electric grid, hydraulic pumps offer greater deployment flexibility and can be mounted on excavators, barges, or skid frames. This makes them particularly valuable for contractors and operators who need powerful, portable pumping solutions in challenging environments.

Each submersible slurry pump type serves a distinct purpose, and choosing the right one depends on factors like mobility, power availability, site conditions, and desired throughput.

Comparing Hydraulic vs. Electric Submersible Slurry Pumps

When choosing a submersible slurry pump, understanding the operational differences between hydraulic and electric variants is critical for achieving optimal performance and cost-efficiency. Both types are designed to handle abrasive, high-solid-content fluids in submerged environments, but they differ significantly in terms of power source, mobility, and application suitability.

An electric submersible slurry pump is often preferred for installations where stable electrical power is available. These pumps are known for their operational simplicity and low maintenance requirements. Their sealed electric motors, coupled with features like variable frequency drives and thermal protection, make them ideal for continuous-duty use in controlled environments such as wastewater facilities, processing plants, and slurry sumps. Electric systems are also more energy-efficient over long periods, making them cost-effective for fixed, long-term applications.

In contrast, a hydraulic submersible slurry pump is powered by a hydraulic power unit, providing superior torque and performance under extreme conditions. These pumps are built for versatility and are commonly used in dredging, mining, and remote job sites where electric infrastructure is unavailable. The robust nature of hydraulic systems allows them to excel in harsh environments with high concentrations of solids and highly viscous fluids. Their compact form factor and ability to integrate with excavators or skid-mounted systems make them a go-to solution for mobile operations.

The decision between hydraulic and electric largely depends on job site requirements. If the project demands frequent relocation, deep submersion, or operation in power-limited areas, a hydraulic submersible slurry pump offers unmatched flexibility. On the other hand, when working in environments with consistent electrical access and fixed pump locations, an electric submersible slurry pump delivers reliable, low-maintenance performance. Carefully matching pump type to job conditions ensures the equipment performs efficiently and cost-effectively throughout its service life.

Common Applications Across Industries

The submersible slurry pump is a highly versatile solution used across a wide range of industries that deal with challenging fluid environments. Its ability to operate while fully submerged in abrasive, high-solids slurries makes it indispensable for sectors requiring reliable material transfer, dewatering, and sediment management.

In the mining industry, submersible slurry pumps are widely deployed for handling tailings, dewatering underground shafts, and transferring ore slurry. Their robust construction and high solids-handling capacity allow for efficient movement of abrasive materials that would quickly degrade standard pumping systems. In remote mining locations, the hydraulic submersible slurry pump is particularly useful due to its portability and power independence.

In construction, these pumps are commonly used to dewater trenches, pits, and excavation sites where groundwater or rainwater can stall operations. The electric submersible slurry pump is often chosen for foundation works and site preparation, especially when electrical infrastructure is available and continuous pumping is needed to maintain a dry work area.

Dredging operations also rely heavily on submersible slurry pumps for sediment removal, pond reclamation, and marina or harbor maintenance. These pumps can handle a wide range of materials—from fine silt to coarse sand and gravel—making them ideal for aquatic environments. The hydraulic submersible slurry pump is often favored in dredging for its ability to be mounted on excavators or barges and operate in submerged or hard-to-access areas.

In the wastewater sector, submersible slurry pumps play a vital role in handling sludge, grit, and other dense materials within treatment plants. Their non-clogging impeller designs and corrosion-resistant construction allow them to function reliably in corrosive and high-viscosity fluid conditions. The electric submersible slurry pump is commonly used in these applications for its automation compatibility and energy efficiency in continuous operations.

Across all these sectors, the submersible slurry pump stands out as a reliable, durable, and adaptable solution for demanding fluid handling tasks.

Installation and Operational Best Practices

Proper installation and operation are essential to maximizing the efficiency and lifespan of a submersible slurry pump. Whether deploying the unit in a mining pit, dredging site, or industrial facility, initial site preparation and pump positioning play a critical role in long-term performance. The pump should be positioned upright and fully submerged to prevent air entrainment and ensure consistent slurry intake. When operating in sediment-heavy environments, it’s important to place the pump in a sump or a stabilized section of the work zone to reduce wear from excessive solids accumulation.

Electrical and hydraulic safety precautions are vital, particularly during initial setup and regular operation. For an electric submersible slurry pump, ensure that power connections are waterproof, properly grounded, and equipped with overload protection. Cable routing must minimize wear points and avoid sharp edges. In the case of a hydraulic submersible slurry pump, all hydraulic lines should be pressure-tested and fitted with quick-connect couplings to prevent leaks and system failures. Operators should routinely monitor fluid levels in hydraulic power units and ensure adequate cooling flow.

Routine inspection and preventive maintenance are key to avoiding costly downtime. Regularly check for signs of wear on impellers, seals, and pump casings. Establish a schedule for replacing wear parts based on material type, runtime, and environmental conditions. Both electric and hydraulic systems benefit from proactive seal monitoring to prevent slurry ingress into the motor or power unit.

To optimize performance, maintain a steady operating flow, and avoid frequent start-stop cycles that can stress mechanical components. Adjust pump positioning as slurry levels change to maintain submersion and consistent performance. Additionally, using a variable frequency drive (VFD) with an electric submersible slurry pump or flow control valves with a hydraulic submersible slurry pump can fine-tune operations and reduce energy or fuel consumption. Adhering to these best practices ensures operational reliability and extends the effective service life of your submersible slurry pump in even the most demanding conditions.

Troubleshooting and Performance Optimization

Despite being built for rugged conditions, a submersible slurry pump can encounter performance issues over time due to the harsh nature of the materials it handles. Common problems include clogging from oversized solids, cavitation caused by insufficient submersion or air ingress, motor overheating due to overloading, and seal failure from abrasive slurry infiltration. Identifying and addressing these issues early is essential to maintaining operational efficiency and preventing costly downtime.

Clogging is typically the result of oversized debris or fibrous materials obstructing the impeller or suction inlet. Regular inspection and proper screening at the pump intake can help mitigate this. Cavitation often presents as unusual vibration or noise and may be linked to low fluid levels, air pockets, or improper pump positioning. Maintaining full submersion and avoiding flow restrictions are key to preventing this issue.

For an electric submersible slurry pump, motor overheating can occur if the pump runs dry or operates under excessive load. Thermal sensors and automatic shutoff systems can protect the motor, but operators should also monitor amp draw and fluid temperatures during operation. In a hydraulic submersible slurry pump, overheating may point to low hydraulic fluid levels, inadequate cooling, or blocked return lines. Routine fluid checks and proper HPU setup are crucial for system health.

Seal failure is another critical concern, especially when dealing with high-abrasion slurries. Visual checks for oil leakage, increased vibration, or a drop in pump performance can signal seal wear. Using double mechanical seals with oil chambers and replacing them at recommended intervals helps maintain reliability.

To support proactive maintenance, many modern systems incorporate sensors and digital monitoring tools. Flow meters, pressure gauges, and temperature sensors enable real-time diagnostics, allowing operators to make adjustments before issues escalate. Whether running an electric submersible slurry pump or a hydraulic submersible slurry pump, integrating these tools into your maintenance program can significantly improve uptime and pump longevity.

Choosing the Right Submersible Slurry Pump for Your Application

Selecting the right submersible slurry pump starts with understanding the specific requirements of your application. Before choosing a model, it’s essential to consider key performance factors such as the type of material being pumped, the required flow rate, discharge head, and the size and abrasiveness of the solids involved. These variables directly impact the pump’s design, impeller type, and motor capacity.

Site conditions also play a crucial role. For example, remote locations without electrical access may require mobile solutions, while fixed facilities with consistent power supplies are better suited for stationary systems. Environmental factors like slurry temperature, chemical composition, and fluid viscosity must also be evaluated to ensure material compatibility and long-term durability.

When comparing pump options, the choice between a hydraulic submersible slurry pump and an electric submersible slurry pump should align with operational priorities. A hydraulic unit is ideal for high-demand applications requiring mobility, high torque, and the ability to function in deep or restricted-access environments. It is particularly effective in dredging, mining, or construction scenarios where heavy-duty pumping is necessary and power sources are limited.

In contrast, an electric model offers a more energy-efficient solution for continuous operation in controlled settings. It’s well-suited for wastewater treatment plants, industrial sumps, and other fixed installations where reliable electrical infrastructure is available. Considering these real-world needs allows contractors and operators to match the right pump configuration to the job at hand, ensuring consistent performance, minimal downtime, and optimized operational costs.

Future Trends in Submersible Slurry Pump Technology

As industrial demands evolve, the technology behind the submersible slurry pump continues to advance, offering improved durability, efficiency, and automation. One of the most significant areas of development is in wear-resistant materials. Manufacturers are now incorporating advanced alloys, ceramic coatings, and engineered polymers to extend component life in highly abrasive environments. These improvements not only reduce maintenance requirements but also increase pump uptime and overall reliability.

Smart sensor integration is another key innovation shaping the future of slurry pumping. Built-in diagnostics and real-time monitoring systems are being added to both electric submersible slurry pump and hydraulic submersible slurry pump models. These technologies track parameters such as vibration, temperature, and flow rates, alerting operators to potential issues before they lead to equipment failure. The result is a shift toward predictive maintenance, minimizing downtime and lowering total operating costs.

Energy efficiency is also a major focus area. New motor technologies and control systems, such as variable frequency drives in electric pumps and load-sensing hydraulics in hydraulic units, are helping operators reduce power consumption without sacrificing performance. In addition, remote monitoring and automation capabilities are making it easier to manage pumps from centralized control rooms or mobile devices, improving responsiveness in dynamic job environments.

The future also points toward hybrid systems and modular configurations, allowing pumps to be customized more easily for specific applications. These adaptable designs are ideal for projects requiring flexibility in deployment, such as those in remote or multi-stage operations. With these innovations, the next generation of submersible slurry pump solutions promises greater efficiency, smarter controls, and longer service life in even the most demanding industries.

Conclusion

As industrial operations become more demanding and efficiency-driven, selecting the right submersible slurry pump is more critical than ever. Whether choosing a hydraulic submersible slurry pump for mobile, high-torque performance or an electric submersible slurry pump for energy-efficient fixed installations, understanding pump design, application requirements, and maintenance best practices ensures long-term reliability and cost control. With ongoing advancements in materials, monitoring, and smart automation, the future of slurry pumping is set to deliver even greater performance, adaptability, and value across diverse industries.